When it comes to maintaining and optimizing the performance of Netzsch equipment, understanding the importance of spare parts is essential. Netzsch is renowned for its high-quality machinery used across various industries, including food processing, pharmaceuticals, and chemical manufacturing. This article will guide you through the key aspects of Netzsch spare parts, ensuring you have the knowledge needed for efficient maintenance and operation.

Importance of Netzsch Spare Parts

Using genuine Netzsch spare parts is crucial for several reasons:

- Quality Assurance: Genuine parts are designed specifically for Netzsch equipment, ensuring compatibility and reliability.

- Performance Optimization: High-quality spare parts help maintain optimal performance, reducing downtime and improving efficiency.

- Longer Equipment Life: Regular replacement of worn or damaged parts can extend the lifespan of your machinery, leading to significant cost savings over time.

- Safety: Ensuring that all components are in good working order is vital for the safety of your operations.

Common Types of Netzsch Spare Parts

Understanding the different types of spare parts available can help you make informed decisions. Here are some common categories:

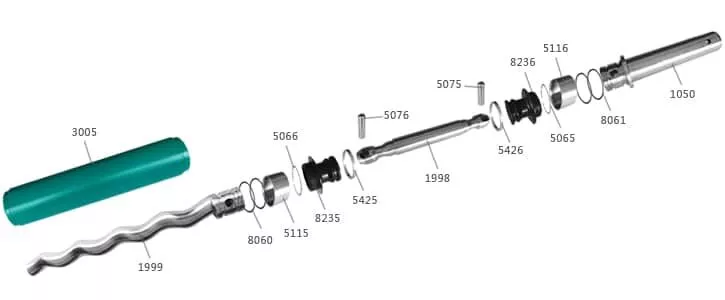

- Mechanical Parts: This includes gears, bearings, and seals that are essential for the moving components of the machinery.

- Electrical Components: These parts, such as motors and control panels, are crucial for the operation of Netzsch equipment.

- Hydraulic Parts: Hydraulic pumps and cylinders are key to ensuring the fluid dynamics within the system function correctly.

- Filters and Screens: These components help maintain product purity and protect machinery from contaminants.

Tips for Sourcing Netzsch Spare Parts

When sourcing Netzsch spare parts, consider the following tips:

- Buy from Authorized Dealers: Ensure that you purchase spare parts from authorized Netzsch dealers to guarantee authenticity and quality.

- Keep an Inventory: Maintaining an inventory of essential spare parts can help reduce downtime during unexpected breakdowns.

- Regular Maintenance Checks: Schedule regular checks to identify which parts may need replacement, allowing for proactive maintenance.

- Consult the Manual: Always refer to the equipment manual for specific parts and recommendations.

Conclusion

Having a solid understanding of Netzsch spare parts is vital for anyone involved in the operation and maintenance of Netzsch equipment. By prioritizing genuine parts, recognizing the importance of regular maintenance, and knowing where to source these components, you can ensure the longevity and efficiency of your machinery. Whether you are in the food industry or pharmaceuticals, investing in quality spare parts is an investment in your operational success. Remember, the right spare parts can make all the difference in keeping your Netzsch equipment running smoothly.